Meat Fat Meter

Measure meat fat in seconds, Meat Fat Meter is a hand held device to analyze meat fat (lipid) content percentage instantly. Easy to use, instant results & accurate. Ensure quality from your supplier and to your customers.

To purchase, Click on Get a Quote Now below:

What is a Meat Fat Meter?

Fish Fat Meter is a hand held device that measures fish fat (lipid) content percentage in seconds. It’s accurate, easy to use and trusted world wide by top researchers, Scientists, fish & seafood market quality assurance specialists.

Fish Fat Meter is a hand held, durable for outdoor use and non-destructive device so that you can use the fish safely after measuring it.

Results in seconds

Accurate & instant results to make on the spot decisions.

Handheld & Portable

Just like the size of a smartphone, carry it anywhere you like.

Rugged & Durable

Made for outdoor use and water proof to IP65 standards.

Long battery life

Up to 8 hours of all day use. Go for a long field measurements.

Non destructive

No harm done to your fish or the meat being measured.

Ease of use

Anyone can measure right out of the box, with no special training.

How does the Meat Fat Meter work?

Meat Fat Meter measures meat fat (lipid) content percentage by measuring water content sensed by the micro-strip sensors. The sensors measure the amount of water in the tissue and by using proprietary algorithm, it translate the data into meat fat (lipid) percentage.

Meat Fat Meter’s algorithm was developed and refined over years of research, experience & customer feedback. It’s been tested, proven and trusted by world’s most demanding Researchers, Scientist and Lab Technicians for years.

How accurate is the Meat Fat Meter?

The accuracy of the Meat Fat Meter depends on the overall fat (lipid) content percentage of the entire meat, please refer to the accuracy guide.

How to read the accuracy guide: when using the Meat Fat Meter and you get an overall meat fat percentage of 2% to 15%, the accuracy is about ± 0.5% to ± 1.0%.

If the meat fat (lipid) content percent is from 16% to 30%, the accuracy is about ± 1.0% to ± 2.0% and so on. As the total meat total fat (lipid) content increases, so does the percentage of variance in accuracy.

| Meat Fat (lipid) content percentage results | Accuracy |

|---|---|

| 2% to 15% | ± 0.5% to ± 1.0% |

| 16% to 30% | ± 1.0% to ± 2.0% |

| 31% and above | ± 2.0% to ± 4.0% |

What types of meat can the Meat Fat Meter measure?

14 meat types with 29 settings!

The Meat Fat Meter can measure 14 fish types of meat with 29 possible setting.

For every purchase or rental, you get to choose up to 4 types of meat to be pre-calibrated to the device and a “Research” setting to make your own calibration if needed.

| Beef Mince grind Homogenized, blended | Chicken (various types) MRM lean chicken MRM & 10% water | Beef burger 100% Natural Beef + 5% additive such as: salts, spices, onion, fillers, binding agents | Pork Sausage (with various additives) Mince grind |

| Beef (Australian) Mince grind | Horse/Pony Icelandic horse meat | Hamburger 100% Natural Beef + 12.5% additives such as: salts, spices, onion, egg,other fillers, binding agents | Lamb Sausage (with various additives) Mince grind |

| Beef (MRM beef & water) Beef meat recovered using Baader M/C + 8% added water (Mechanically recovered meat emulsion) | Lamb (various types) Mince grind | Smoked Ham Mince grind | Icelandic Sausage (with various additives) Mince grind |

| Pork/Beef 50%/50% – Mince grind 70%/30% – Mince grind | Deer (various types) Mince grind | Luncheon Meat Mince grind | Salami Mince grind |

| Pork 100% pork beef 100% pork belly Pork with additives Pork with 10% water Various pork trims | Reindeer (various types) Mince grind | Beef Sausage (with various additives) Mince grind | Research Setting Used to measure product where no specific calibration is available (Custom calibration) |

Research

Conduct Government, University & Non-profit research projects.

Quality Control

Objective data driven results to ensure consistent quality.

Grocery Stores

Inspection and labeling of proper fat content percentage.

Who & How do people use the Meat Fat Meter?

Researchers, Scientists & Lab Technicians

Used in key US Government research projects to monitor meat processing, inspections and conduct audits.

Meat Market Quality Assurance

To measure proper quality from suppliers to improve logistic or storage techniques. Determine fat percentage for consumer awareness.

Meat processors, Distribution and Meat Logistic

To ensure proper labeling of meat to certain consumer markets such as low fat, no fat or lean fat labeling.

Restaurants

To ensure meat received from suppliers meets agreed upon fat content level.

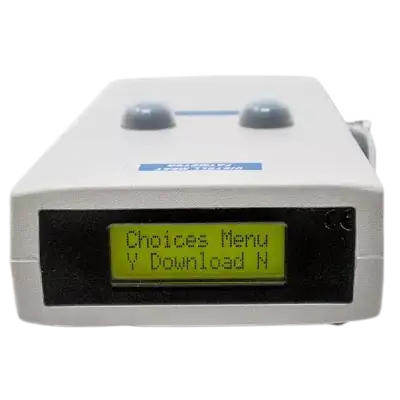

Easy To Use & Rugged

Only three buttons: On/Off, Reset & Read. Turn it on, select the fish type & measure. Yes, it’s that simple!

Ease of use:

Rugged & Ready for outdoor use:

Meat Fat (lipid) content percentage results in Seconds & Non-destructive

Depending on the size of the meat, take 1 to 4 measurements per meat sample for reliable & accurate reading. You’ll then get an “average” of those readings as a result.

The Meat Fat Meter only emits approximately 1 mW (mili Watt) to take the readings, thus doing no harm to the meat so you can sell it with confidence to your customers.

Any limitations of the Meat Fat Meter?

No device is perfect and here are some limitations of the Fish Fat Meter you need to be aware of:

Meat Fat Meter comes in 2 sizes: FFM 992 (Small) & FFM 1092 (Big)

Meat Fat Meter offers 2 sizes depending on the size of the fish you’re measuring.

Which size do i need? We recommend the following:

- In general, meat sample smaller than 1 lb, we recommend the small MFM 992 device.

- For meat samples bigger than 1 lb, we recommend the big MFM 1092 device.

| MFM 992 (Small) | MFM 1092 (Big) | |

| Device Size | 5.9 x 3.15 x 1.18 inch (150 x 80 x 30 mm) | 7.68 x 3.94 x 1.57 inch (195 x 100 x 40 mm) |

| Weight | 0.88 lbs (400 grams) | 1.6 lbs (725 grams) |

| Sensor size | 1.97 x 1.0 x 0.4 inch (50 x 25 x 10 mm) | 3.15 x 1.0 x 0.4 inch (80 x 25 x 10 mm) |

| Shipment weight for 1 device | 6.6 lbs (3 kg) | 7.25 lbs (3.5 kg) |

| Minimum meat sample needed | 0.5 lbs (250 gr) of minced meat with at least 0.12 to 0.31 inch (3 to 8 mm) grind | 0.66 lbs (300 gr) of minced meat with at least 0.12 to 0.31 (3 to 8 mm) inch grind |

| Minimum meat sample thickness needed | 1 inch (25 mm) |

| Meter casing material | ABS plastic with IP65 water proof |

| Sensor operating frequencies | 1.975 GHz (+/- 20 MHz) |

| Battery type | Internal rechargeable: Nickel Metal Hydride (NiMH) |

| Battery life | 8 hrs continuous use |

| Battery recharge time | 12 to 15 hours from empty |

Meat Fat Meter FAQ

Other Related Products

Certified Quality Reader 3.0

Measure Quality of Fish, Meat & Produce with online analysis

To Purchase, call or email